At UPL, we demonstrate our commitment to conduct business responsibly through active assessment of our products at every stage in their life cycles, from the sourcing of raw materials, through manufacture and use, to eventual disposal. At each stage of the value chain we address environmental and social issues through sustainable design, green chemistry, resource efficiency and responsible marketing. Our product stewardship process adds value to our products by minimizing the risk and improving quality.

Our constant endeavour is to provide solutions to optimise farm productivity for the farmers through products that are innovative, cost-effective, and of highest quality standard. Our quality management system ensures that the quality of our product is maintained consistently throughout its life cycle . We have a dedicated team focusing on quality control through periodic audits based on highest international standards. We also review our quality management system to continuously improve our product and service quality.

Effective quality control also provides opportunities to identify any existing gap with respect to our products and accordingly we take preventive & corrective action to close such gaps. It helps us identify and adopt with changing regulatory landscape and manage complexities of ensuring quality across business functions.

We continuously put effort to ensure highest product quality through valuable inputs received through different modes e.g farmer's feedback process, satisfaction surveys and other engagement mechanisms.

We are a research-driven Company and address how products can be evolved and adapted to diverse customer needs. We extended our business model beyond core products to solutions, providing customers allied services e.g crop protection chemicals spraying, price trends and ancillary products supply. We also offer innovative products that help conserve ground water, particularly relevant in drought conditions. All these efforts over the years have resulted into increased customer confidence and made us an automatic choice for our customers.

Customer Satisfaction Survey

We give prime importance to our customers as they are the stakeholders who use our products and they can contribute immensely in product development. For specific products we conduct post-marketing audits which not only acts as a driver to enhance customer satisfaction level but also helps us serve better by understanding the need of the customer.

In farming, timely advice with right products and right practices is key. In response to this evident need we launched Adarsh Kisan Centre (AKC), a remote advisory contact center for farmers in India. We have such centres at various locations in India like Mumbai, Visakhapatnam and Chandigarh .Our customers can connect with us through a toll free number provided on all product packaging for any queries and complains. All the queries and complaints from customers are taken on priority and resolved. In case if a customer requires further assistance, the case is escalated to the field executive team of UPL, who visits the location and resolves the issue personally. We use our call centers to take feedback from registered farmers at AKC. The scope of survey is broad which includes product availability, usage and market access of harvest. The survey is based on various parameters such as availability product in market, usage of the product, market access of harvest and others. These surveys are an important tool for us to identify the gaps in our systems and resolve them on priority. We also provide following additional services to farmers under this initiative:

The field of agriculture is continuously changing. Staying abreast with the latest advancements is a challenge especially for the far flung or marginal farmers. Truly putting the 'Farmer First' in our actions, we address this challenge through its initiatives. One such initiative is “Unimart” which is a chain of farm advisory and solution centres in India and Africa that provides expert advice, quality products and necessary guidance to farmers. Since 2009, Unimart has been a one-stop solution center providing expert advice, quality products along with necessary guidance to enhance farming practices. The result of this far-reaching initiative has been an attractive increase in income per acre of crop produce translating into an improved standard of living across regions

Adarsh Farm Services is one such initiative whereby we transform farming through farm mechanisation technology and services. UPL's Adarsh Farm Services offers high-tech tractor-mounted spray equipment that results in time and cost savings for farmers on one hand and minimizes crop damage on the other. As we extend this service to marginal farmers too, we are building direct relationships with farming community.

1.2 millions

average covered

More than

1 million

farmers serviced

3 states covered –

Rajasthan, Punjab, Haryana

More than

15 crops covered -

kinnow, cotton, wheat, paddy, sugarcane, soybean, maize, potato, mustard etc.

UPL's Trust++ in Latin America allows thousands of banana growers access to quality fungicides manufactured by UPL, which facilitates the permanent monitoring of Sigatoka.The platform urges banana farmers to 'know more and work better' by providing them easy access to information on contemporary technologies, markets and global developments, weather reports, online record books for stock control etc.

More than

15,000 acres covered

by the Trust++ service

As we look to the future, population growth, migration and climate change will all pose additional challenges to global food security – we have to anticipate these changes and be innovative and agile in our response. If we are to ensure the world's population can access the vital nutrients they need, we need to continue drawing on local knowledge and creating innovative solutions that are accessible to farmers of all sizes. We established a reputation for being a pioneer as we were first to manufacture groundbreaking products like Zeba. We invested in reinforcing R&D capabilities coupled with focusing on off - patent molecules. We have 305 members in research and development team that continuously work on introducing innovative and differentiated products and processes. We design our manufacturing processes following principles of green chemistry. For example, the catalytic processes generating low or no wastes are preferred over chemical processes which invariably generate high wastes although the capital investment in catalytic processes could be higher.

The formulations are tested extensively for bio-efficacy at the development stage before going to the market launch. Care is taken to develop safe, easy to handle and environmentally friendly formulations keeping in the mind “The Farmer First” motto of Company. We conduct simulations of the processes to assess safety issues using advance thermal screening and hazard analysis for raw materials, reaction mixtures, intermediates and finished product to finalise the safety precautions during their use and also during reaction conditions. At UPL, we have established dedicated departments for focusing on new technology, transfer of the technology at plant level and improving process capability thereby creating an environment for driving innovation along with process excellence across our operations.

UPL Energy Management Cell is committed for continual improvement in energy efficiency by establishing effective energy management programs in operations and all new projects. Energy Cell is presently focusing on identifying and implementing projects which reduce specific consumption of electrical, thermal and water resources. Following are some of the key roles of Energy Cell

Maxpro department focuses on cost reduction and seamless transfer of technology or process to plant. Some of its key roles are as follows:

Maxpro+ works on variability reduction of process, improving process capability and productivity which includes the following activities:

At UPL, we understand the importance to protect innovation by filing patents both nationally and globally. We respect Intellectual Property (IP) of others and create our own IP for the products and processes developed by the Research and Development Centres. Patents are obtained in the countries of interest and appropriate measures are taken to safeguard the IP.

Our innovation approach is testimony to our belief that technological progress is the foundation of efforts to achieve environmental objectives. Our innovative products are designed with increased resource-use efficiency and greater adoption of clean and environmentally sound technologies and industrial processes thereby contributing to achieving SDG 9– Industry, Innovation and Infrastructure.

Due to changing weather pattern and unpredictable rainfall, access to water is a major challenge. Water is not evenly distributed around the globe, and our needs for water isn't the same everywhere, and hence people resort to alternate sources of water. Two billion people use aquifers as primary drinking water sources and the ground water accounts for roughly one-third of the world's water withdrawals.

As the world population increases and proportionately food demand increases, we see that the water reserves are falling in several of the world's major aquifers. As the global aquifers are becoming more depleted the need to supply water to areas where it is needed most is a pertinent issue.

A closer look into the ground water recharge rate across the world clearly shows that the ability for this vital source of water to sustain us into the future is in question, as increasing ground water stress is impacting on the ability of a region to produce a sustainable food source for its population.

Zeba is able to achieve a reduction of 5%-20% of water used by the growers, depending on the environmental and management conditions at the time, on top of any other water conservation strategy employed. Apart from this, Zeba helps in efficient use of nutrients (NUE) and reduces their negative environmental impact e.g Nitrogen leaching through its impact on aggregation and cations exchange in the soil profile. Successfully managing water and nutrient use efficiency in this way offers the ideal environment for soil microbes to thrive.

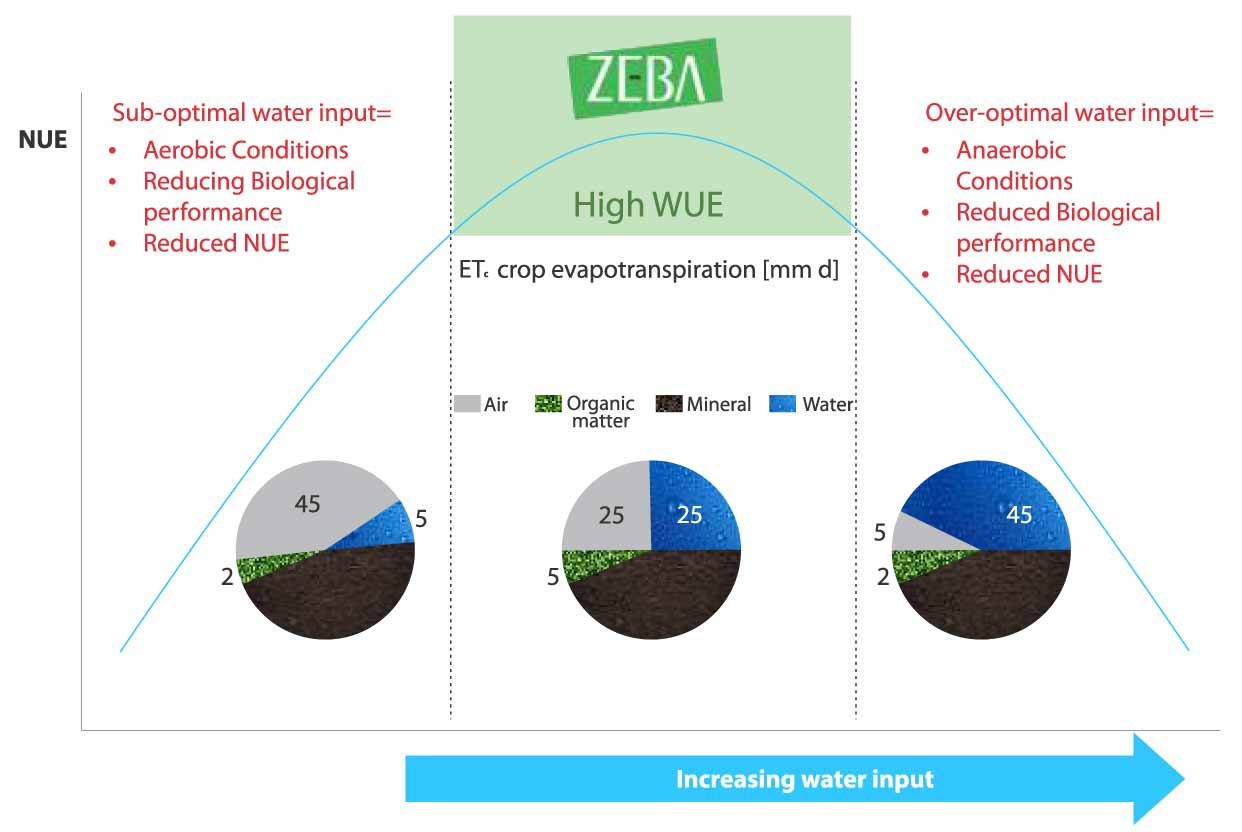

In the following chart we can see how performance of nutrients (Nitrogen) can be optimised with appropriate water supply, but as it becomes less than optimal for either excess or deficient, then the ability of a crop to perform is reduced. This is where water becomes the biggest limiting factor to crop production and is integral to all other soil and plant processes.

If we can regulate the water which is delivered to crops and reduce the impact of excess nutrients supplied without disturbing soil's natural functions, we can reduce the water and nutrient losses for the benefit of the crop, environment and mankind.

It is a fact that delivering excess water above a crops usable requirements, will have potential to reduce yield and increase the negative impact on the environment. Similarly, too little water has a similar impact in crop production as the crop cannot process the nutrients one applies, again leading to loss of Nutrient Use Efficiency (NUE). This optimal position of adequate water which is increases the use efficiency of nutrients applied, is where Zeba performs.

It is only the presence of a healthy crop that drives our portfolio forward and delivers a sustainable business model. The most important bio stimulant known to our industry is water which can create the environment for a healthy ecosystem to promote nutrient access to plants. Zeba through its effects on improving water and nutrient management programs, soil aggregation and microbial support can be a pivotal part of any “sustainable farm initiative” contributing to the creation of a balanced system, promoting an active, functional soil solution and rhizosphere, for the benefit of the plant, grower and the environment